Detection Of The Vertical Surfaces Of The Ceramic Plate

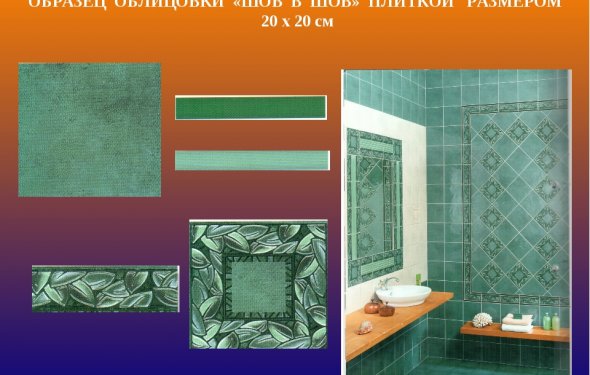

The main means of diagnosing is evaporation (Figure 28, a), "Shov in Shoves" (Figure 28, B) and diagonal (Figure 28, V). The latter is the most labour-intensive method, but has a high decoration.

Rhys. 28. The kinds of streets are: a-a-a-a-a-a-a-a-a-a-a-a-a-ha-a-a-a-a-a-a-a-a-a-a-a-a-a-a-a-a-a-a-a-a-a-a-a-a.

The rolephened fountains carry a seamless, high quality.

The main features of the vertical surfaces are plintos, caps, main plane of the lining (semi walls), fries and carnivals. In addition, angles (introducing and internal) and built-in sanitary details - ceramic soaps, semi-trailers, etc.

Plintus and carnival tend to be marked with beans, fries with sticks different from the basic plane of colour or drawing.

In the face of concrete walls, to make concrete steroid, it is insect with a pneumatic 2-CMR pistol.

Wooden walls and partitions in front of the lining shall be tampered with. The shell shall be 20 to 25 mm long and shall be applied to the wooden surface with vertical and horizontal brushes 20 to 25 mm thick and a width of 30 to 35 mm, to which the layer of thickness or ruberoide is attached. It shall be accompanied by a metal grid with 10X10 or 15X15 mm. The surface prepared to be labelled in this way does not change with voluminous changes in wood and ensures the safety and normal operation of the plate.

When the vertical surfaces are lit, the ceramic plug shall be placed on the cement solution of the composition by mass 1:4 - 1:6 (cement : sand) strength 7, 5 MPa or on the complex cement-limestone solution of the composition by mass 1:1:4 (cement : evegetation: sand). In both cases, large sand is used in solutions. Mobility of solutions 5 - 6 cm.

Before the lining for a better clutch with its base, the surface is purified from dust, mud, water washed, fat stains remove 5 per cent of the water solution of the calcinated soda. The thickness of the solvent shell shall be at least 7 mm and not more than 15 mm.

The outer surface of the ceramic stove before the solution is stacked requires a low wet grinder to ensure a high clutch clutch with a base.

Water resistant plastic solutions are used to fill the stitches between the stoves, preventing the destruction of the lining by deformation of the base, shell, stoves and stitch material. Usually use plastic cement solution with the addition of polyvinylacetate dispersion or latex, as well as hyper and mela-based combinations.

The width of vertical and horizontal stitches shall be the same when the walls are lit and not exceed 3 mm.